The Evolution of Plastic Moulds

Plastic molding is a cornerstone of modern manufacturing,

enabling the creation of many plastic products that touch almost every aspect

of our lives. From high-end electronics to everyday household items, plastic

molding processes have revolutionized the industry in their variety, precision

and efficiency.

Understanding

the plastic molding process:

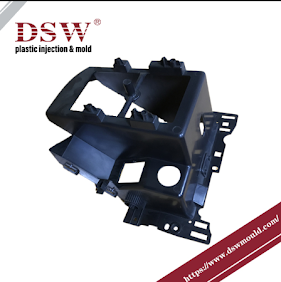

Plastic molding involves a variety of processes, each

tailored to manufacturing needs and requirements. Injection molding, perhaps

the most common technique, involves injecting a molten plastic material into a

mold cavity under high pressure. This process is suitable for the production of

complex parts in high quality and consistent quality and strict tolerance,

making it important in industries such as automobiles, electronics and consumer

goods. Another important method is molding, where molten rubber is poured into

a hollow tube (parison) and pressed to fit the shape of the mold. This method

is often used to produce bottles, containers and other hollow products,

providing good material distribution and dimensional stability.

Additionally, there is rotational molding, which involves

heating and turning the mold into a mold filled with plastic resin. As the mold

rotates, the plastic sticks to its interior, forming an even layer that hardens

into the desired shape. This method is well suited to the manufacture of large

hollow objects such as tanks, sports equipment and kayaks, due to its low

material cost and structural flexibility. Other popular Plastic molding techniques include thermoforming,

compression molding, and extrusion molding, each with unique advantages and

applications. Collectively, these techniques help manufacturers to create a

variety of plastic products, from complex objects to large structures, with

precision.

The

innovation behind plastic molding:

The field of plastic molding is constantly changing,

promoting innovation in materials, technology and manufacturing processes. A

significant advance is the combination of computer-aided design (CAD) and

computer-aided manufacturing (CAM) software, which allows manufacturers to

create complex molding designs and streamline production processes.

unprecedented. This digital marketing capability enables rapid prototyping,

design optimization, and ultimately shorter time to market for new products.

In addition, advances in materials science have expanded the

palette of plastics available for molding, through the development of advanced

polymers, biodegradable resins and recyclable materials. These innovative

materials offer improved performance, improved durability and greater

flexibility, opening up new opportunities for product development across

industries.

Automation and robotics have also transformed the plastic

molding industry, streamlining production processes, improving efficiency and

ensuring consistent quality. From robotic part handling and assembly to mold

change systems and automation, these technologies help manufacturers achieve

higher results, reduce labor costs and maintain quality control standards.

In addition, additive manufacturing, commonly known as 3D

printing, is increasingly entering the plastic molding process, offering rapid

prototyping, tooling production and even final part production. Although it is

still in the early stages of mass production, 3D printing has great potential

to revolutionize the way plastic products are manufactured, especially for

small volume, highly customized applications.

Applications

in all categories:

The evolution of plastic molding techniques has led to their

adoption in many industries, each with its own unique requirements and

challenges. In the automotive sector, plastic molding plays an important role

in the production of interior and exterior components, insulation parts and

structural components that contribute to vehicle safety, performance and fuel

efficiency. From dashboard panels to bumpers to intake manifolds, plastic

materials abound in modern cars, due to their light weight, cost-effectiveness

and structural flexibility.

Apart from automobiles, electronics and packaging, Injecton moulding finds applications in the aerospace, healthcare,

construction and consumer goods industries, among others. From airplanes and

medical devices to building materials, toys and electronics, the impact of

plastic molding on modern life is widespread and profound.

Important

support:

Although plastic molding has revolutionized the industry and

made our lives better, it also poses major environmental problems, especially

when it comes to plastic waste and pollution. As the world worries about the consequences

of single-use plastics and plastic pollution in oceans and landfills, the need

for support in the plastics industry is on the rise. In response to these

challenges, there is an increasing focus on sustainable practices and materials

in the plastic molding industry. Manufacturers are increasingly using recycled

plastics, bio-based resins and biodegradable polymers to reduce reliance on

virgin plastics and reduce their impact on the environment. In addition,

initiatives such as closed recycling, extended producer responsibility (EPR)

and eco-design principles are gaining traction, driving innovation and collaboration

across the spectrum.

In addition, advances in recycling technologies, such as

chemical recovery and recycling, promise to transform plastic waste into

valuable raw materials for new products, thus closing the loop and creating a

circular economy for plastics. By supporting sustainability, manufacturers can

not only reduce environmental damage, but also improve their reputation, meet

regulatory requirements and in the future present their business in an

increasingly environmentally conscious market.

Conclusion:

Plastic molding is a testament to human ingenuity and

innovation, helping to create many amazing plastic products that improve our

lives in so many ways. From automotive components to electronics to everyday

necessities, plastic molding techniques have become essential in modern

manufacturing, offering unparalleled flexibility, efficiency and cost. As the

field continues to grow, thanks to the advancement of materials, technology and

support strategies, the future of plastic molding holds great promise for meeting

global challenges and making positive changes. By fostering innovation,

adopting sustainable practices, and fostering collaboration across industries,

plastic molding can continue to advance human prosperity while reducing its

environmental footprint, enabling a better, sustainable future for generations

to come.

Comments

Post a Comment